در حال بارگزاری...

به دلیل نوسانات ارزی برای موجودی و قیمت نهایی در واتساپ پیام دهید !!!

در حال بارگزاری...

اتصال

رزوه

نوع دنده

NPT

متریال

استنلس استیل 316

برند

ALFA-SPIRAX-Yoshitake

نوع

ترمودینامیکی تفنگی TD

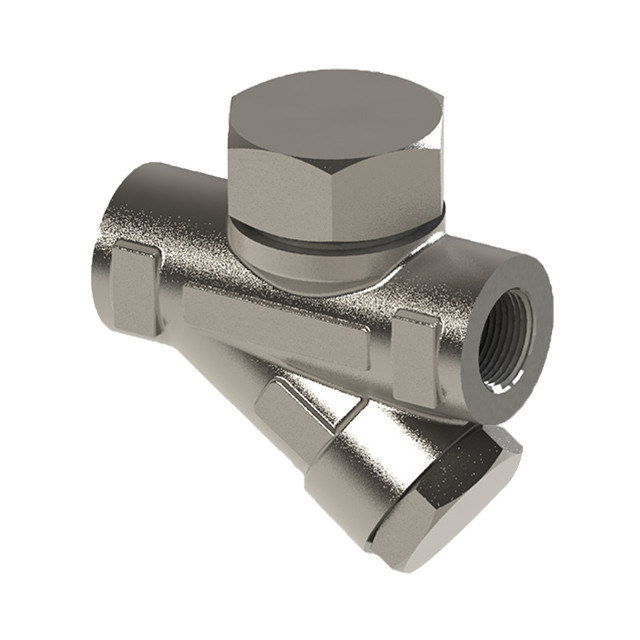

تراپ ترمودینامیکی یا تراپ تفنگی، یکی از تجهیزات ضروری در سیستمهای بخار صنعتی است که به عنوان تله بخار نیز شناخته میشود. این دستگاه با تکیه بر خواص ترمودینامیکی بخار و کندانس (میعانات)، عملکردی کارآمد و مؤثر در جلوگیری از اتلاف انرژی گرمایی دارد.

هنگامی که بخار داغ وارد تراپ میشود، جریانی با سرعت بالا ایجاد میکند که منجر به تشکیل یک ناحیه کم فشار در زیر دیسک میشود. این فرآیند باعث ایجاد خلا و بسته شدن سریع دیسک میگردد. با ورود کندانس یا بخار خنکتر، فشار متعادل شده و دیسک باز میشود تا میعانات تخلیه شوند. این چرخه به طور مداوم تکرار میشود تا از هدررفت انرژی جلوگیری کند.

تراپهای ترمودینامیکی استیل در صنایع مختلفی استفاده میشوند که نیاز به دوام بالا و طراحی فشرده دارند. برخی از کاربردهای کلیدی این تجهیزات عبارتند از:

حذف مؤثر میعانات از سیستمهای بخار بدون افت فشار قابل توجه.

مدیریت شرایط سخت مانند فشار و دمای بالا در صنایع پتروشیمی و نفت.

جلوگیری از تجمع میعانات در تجهیزات فرآیندی حیاتی.

تحمل فشار تا 100 بار و بیشتر، مناسب برای محیطهای صنعتی سنگین.

محافظت از توربینها با بهینهسازی جریان بخار و افزایش بازده انرژی.

افزایش بازده انرژی در نیروگاههای تولید همزمان.

تراپهای تفنگی استیل از قطعات باکیفیت و مقاوم ساخته شدهاند که شامل موارد زیر میشوند:

بدنه (Body): ساختهشده از استنلس استیل برای مقاومت در برابر دما و فشار بالا.

دیسک (Disk): قطعهای متحرک از جنس استیل سختشده که عملکرد تراپ را کنترل میکند.

محفظه دیسک: فضایی طراحیشده برای حرکت دیسک و ایجاد عملکرد بهینه.

ورودی و خروجی: کانالهایی برای ورود بخار و تخلیه میعانات.

نشیمن (Seat): قطعهای دقیق برای اطمینان از آببندی و جلوگیری از نشتی.

تراپهای تفنگی استیل معمولاً از آلیاژهای مقاوم و بادوام ساخته میشوند. دو آلیاژ پرکاربرد عبارتند از:

تراپ تفنگی 304: مقاوم در برابر خوردگی، مقرونبهصرفه و مناسب برای کاربردهای عمومی.

تراپ تفنگی 316: حاوی مولیبدن برای مقاومت بیشتر در برابر خوردگی و سوراخشدن، مناسب برای محیطهای غنی از کلرید.

تراپهای تفنگی استیل در دو نوع اصلی تولید میشوند:

ویژگیها: طراحی فشرده، نصب آسان از طریق اتصالات رزوهای.

کاربردها: مناسب برای خطوط لوله کوچک، راهاندازیهای موقت یا سیستمهایی که نیاز به تعمیر و نگهداری مکرر دارند.

محدودیتها: تحمل فشار کمتر و محدودیت در سایزهای بزرگ.

ویژگیها: اتصالات محکم و مقاوم در برابر نشتی، مناسب برای فشار و دمای بالا.

کاربردها: ایدهآل برای صنایع بزرگ و سیستمهایی که نیاز به تعمیر و نگهداری آسان دارند.

قیمت تراپ تفنگی استیل به عوامل مختلفی مانند جنس آلیاژ، نوع اتصال (رزوهای یا فلنجدار)، و فشار کاری بستگی دارد. برای استعلام قیمت و دریافت مشاوره رایگان، با کارشناسان ما تماس بگیرید.

تراپ تفنگی استیل یک راهحل ایدهآل برای بهینهسازی سیستمهای بخار صنعتی است. با عملکرد مؤثر در حذف میعانات و جلوگیری از اتلاف انرژی، این تجهیزات نقش مهمی در افزایش بازده و کاهش هزینههای عملیاتی ایفا میکنند. برای انتخاب بهترین تراپ تفنگی استیل متناسب با نیازهای خود، با متخصصان ما تماس بگیرید.

The thermodynamic steam trap, also known as a disc-type steam trap, is an essential component in industrial steam systems. It is designed to efficiently remove condensate and prevent energy loss by leveraging the thermodynamic properties of steam and condensate.

When hot steam enters the trap, it creates a high-velocity flow, forming a low-pressure zone beneath the disc. This process generates a vacuum, causing the disc to close rapidly. As condensate or cooler steam enters, the pressure equalizes, allowing the disc to lift and release the condensate. This cycle repeats continuously to prevent energy waste.

Stainless steel thermodynamic steam traps are widely used in industries requiring durability and compact design. Key applications include:

Efficiently removing condensate from steam systems without significant pressure loss.

Managing harsh conditions such as high pressure and temperature in petrochemical and oil industries.

Preventing condensate buildup in critical process equipment.

Withstanding pressures up to 100 bar or more, making them ideal for heavy industrial environments.

Protecting turbines by optimizing steam flow and enhancing energy efficiency.

Improving energy efficiency in cogeneration power plants.

Stainless steel thermodynamic steam traps are built with high-quality, durable components, including:

Body: Made of stainless steel to withstand high temperatures and pressures.

Disc: A single moving part made of hardened stainless steel to control trap operation.

Disc Chamber: A precisely designed space for optimal disc movement.

Inlet and Outlet: Channels for steam entry and condensate discharge.

Seat: A machined component ensuring a tight seal and preventing leaks.

Stainless steel thermodynamic steam traps are typically made from durable and corrosion-resistant alloys. The two most common alloys are:

Grade 304: Offers excellent corrosion resistance, strength, and cost-effectiveness, suitable for general applications.

Grade 316: Contains molybdenum for enhanced resistance to pitting and corrosion, ideal for chloride-rich environments.

Stainless steel thermodynamic steam traps are available in two main types:

Features: Compact design, easy installation via threaded connections.

Applications: Ideal for small pipelines, temporary setups, or systems requiring frequent maintenance.

Limitations: Lower pressure tolerance and limited size options.

Features: Robust, leak-proof connections suitable for high pressure and temperature.

Applications: Perfect for large-scale industrial systems requiring easy maintenance and inspection.

The price of stainless steel thermodynamic steam traps depends on factors such as alloy grade, connection type (threaded or flanged), and operating pressure. For a free quote and expert advice, contact our specialists.

Stainless steel thermodynamic steam traps are an ideal solution for optimizing industrial steam systems. With their efficient condensate removal and energy-saving capabilities, these traps play a vital role in enhancing operational efficiency and reducing costs. To select the best stainless steel thermodynamic steam trap for your needs, reach out to our experts today.